Printing Plate

The color coated steel plate has developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, fine coating, and other continuous unit processes. The coating quality is far more uniform, stable, and ideal than single-piece spraying or brushing on the formed metal surface.

Key words:

Printing Plate

Category:

Product description

Printing Plate Introduction

The color coated steel plate has developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, fine coating, and other continuous unit processes. The coating quality is far more uniform, stable, and ideal than single-piece spraying or brushing on the formed metal surface.

The color coated steel plate has excellent decoration, formability, corrosion resistance, and strong coating adhesion, keeping the color novel for a long time. Because color coated steel plate can achieve sound economic effects such as replacing wood with steel, efficient construction, saving energy, preventing pollution, etc., it has become ideal for making and selecting building plates today.

The design production capacity is 300,000 tons/year, and Siemens program control technology is adopted to realize on-line roller change. The product quality is stable, and all performance indexes meet the national standards.

The color coated steel plate usually refers to the product formed by coating (roller coating) coating or organic bonding film on the substrate's surface and baking, which can be deeply processed into the final product. Foreign countries call it "precoated steel plate" and "plastic steel plate." This product has beautiful colors or patterns when it leaves the factory, also called "color coated steel plate." The name of the color coated steel plate is more prevalent in our country, and it is called "color coated plate" or "color plate" for short.

The company's primary color coating board specifications: 0.14-0.8 mm of thickness, 800-1250 mm of width; 120m/min if unit speed. The coating layer types include polyester, silicon modified polyester, polyurethane, segregated vinyl fluoride, high polyester, epoxy resin, acrylic acid, etc. The production line can produce medium and high-grade products such as building boards and household electrical appliance boards. The line adopts the production process of two coatings and two baking, with complete procedures. The drying furnace adopts an electric heating direct hot air circulation system.

PProduction Line Introduction

Right products depend on advanced production technology and excellent raw materials. Our company has the most advanced production line of color coating board in China. The annual processing of color coated plates reaches 300,000 tons, and the whole set of technology and equipment adopt computer full-automatic control system. Our company's raw materials adopt the products of well-known domestic enterprises such as Taiwan Yieh Phui Enterprise Co., Ltd., Baoshan Iron & Steel Co., Ltd., Anshan Iron and Steel Group Co., Ltd., Wuhan Iron and Steel Group Co., Ltd.

Use of Printing Plate

Buildings: Exterior materials (roof materials, wall materials) for industrial, commercial, residential, and public facilities.

Buildings: Interior materials, interior wall materials, ceiling materials, partition boards, fire doors

Building accessories: Window panels, signboards

Household appliances: Oil/gas boilers, rice barrels, portable gas stoves, etc.

Description of Coil Coating Conditions

For the coating quality, besides the performance of the coating itself, the construction is also essential. We are responsible for providing construction consultation for the sold coatings.

Material: Pretreated galvanized steel plate, cold-rolled steel plate.

Diluent: Special diluent.

Coating viscosity: Bottom and back: 40-50"/25 ℃; Surface: 60-80"/25 ℃ (depending on customer requirements and site conditions)

Film thickness: Front surface: ≥ 20 m; Back: ≥ 5 μm

Drying conditions (pmt): EPO/PCM/PU216-224Cx30 "~ 40" (lower limit of bottom walking and upper limit of surface walking)

Standing time: 10 ~ 30"

Note: The performance of colored steel undercoat is not tested separately but needs to be tested on the undercoat.

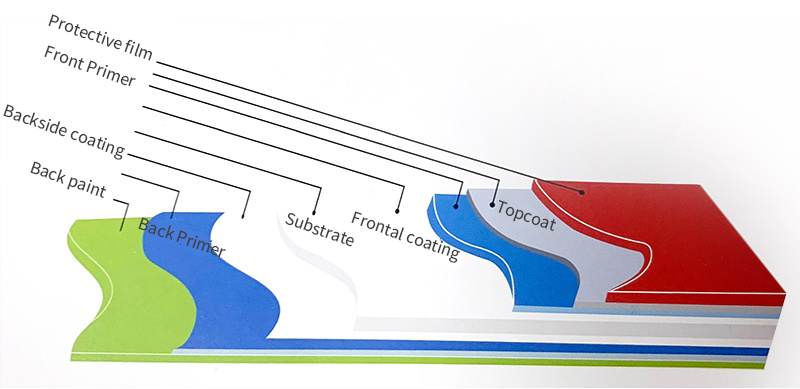

Printing board composition

|

Characteristics of epoxy resin primer coating: Mainly used as a primer. It has excellent adhesion to a wide range of substrates. It has good chemical resistance in many harsh environments. Excellent corrosion resistance. Good matching with various topcoats. High abrasion resistance. It has excellent rheological properties on the coil steel coating line. |

Characteristics of Polyester Resin Topcoat Paint: The coating has good performance, good flexibility, high hardness, and good processability. Good leveling performance on the coil steel coating line. It has good adhesion and chemical resistance. Good weather ability. |

Characteristics of Epoxy Resin Back Paint: The coating has good performance, high hardness, good scratch resistance, and good processability. Good leveling performance on the coiled material coating line. It has excellent adhesion to a wide range of substrates. |

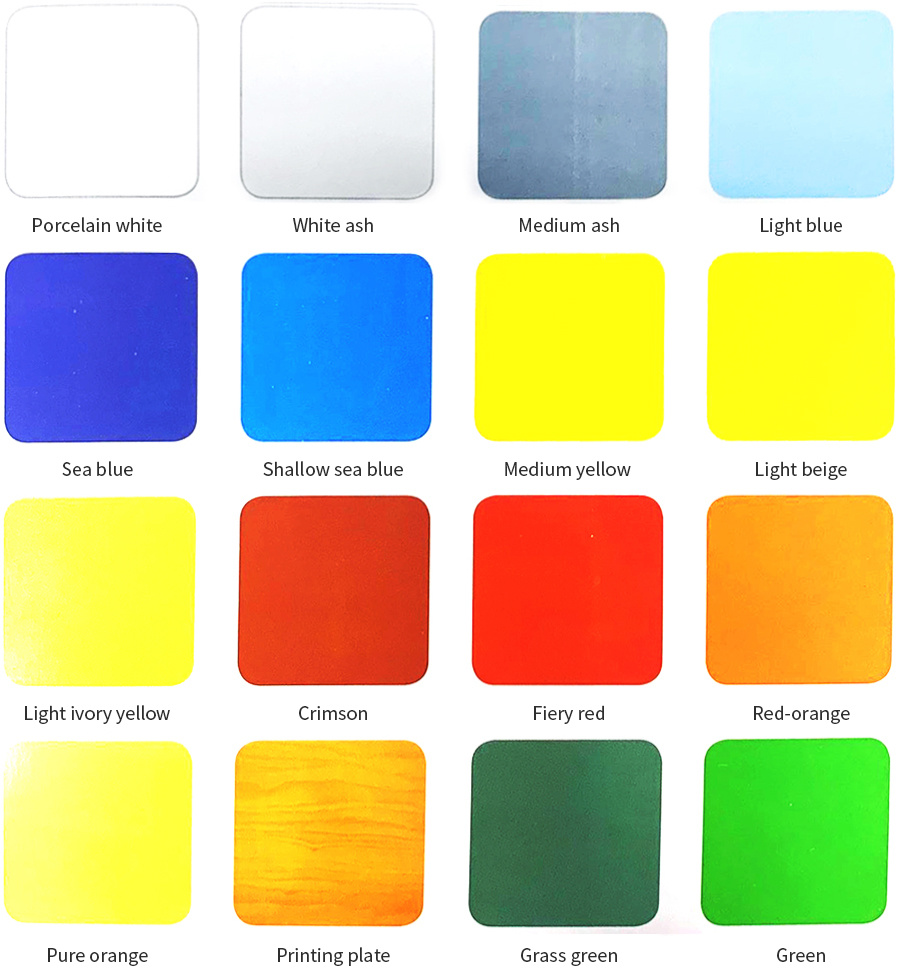

Color Painting Card

Note: Due to printing, the color card's coloration is different from the actual paint color. Please refer to our company's color plate standard card or the color card provided by you if necessary.

Related Products

Message